Find Landscapers Near Me That Use Earth & Turf Products

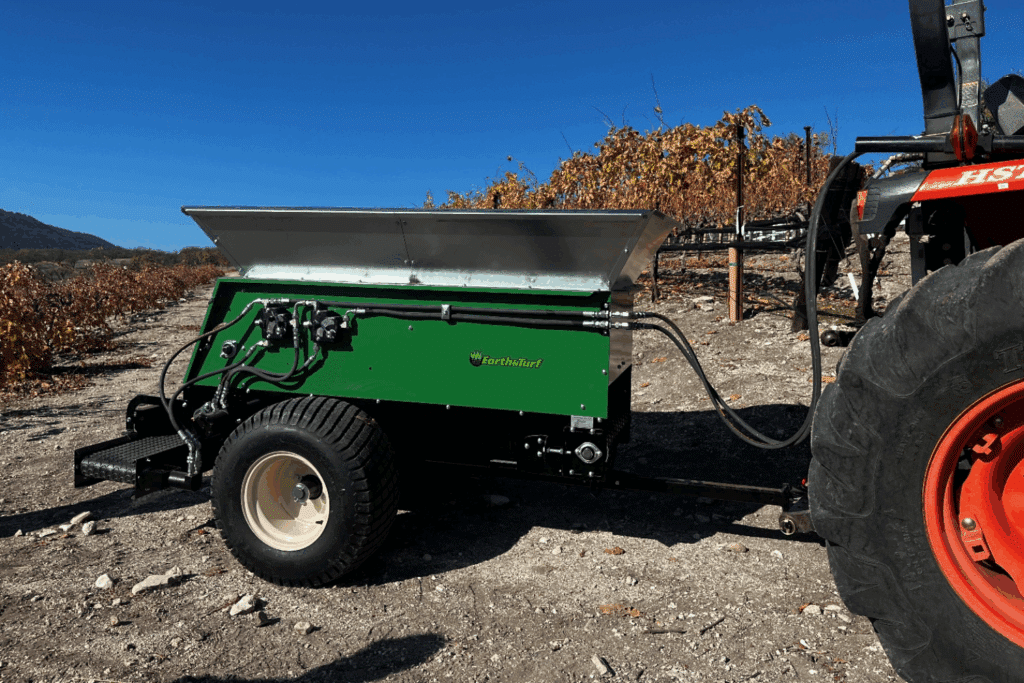

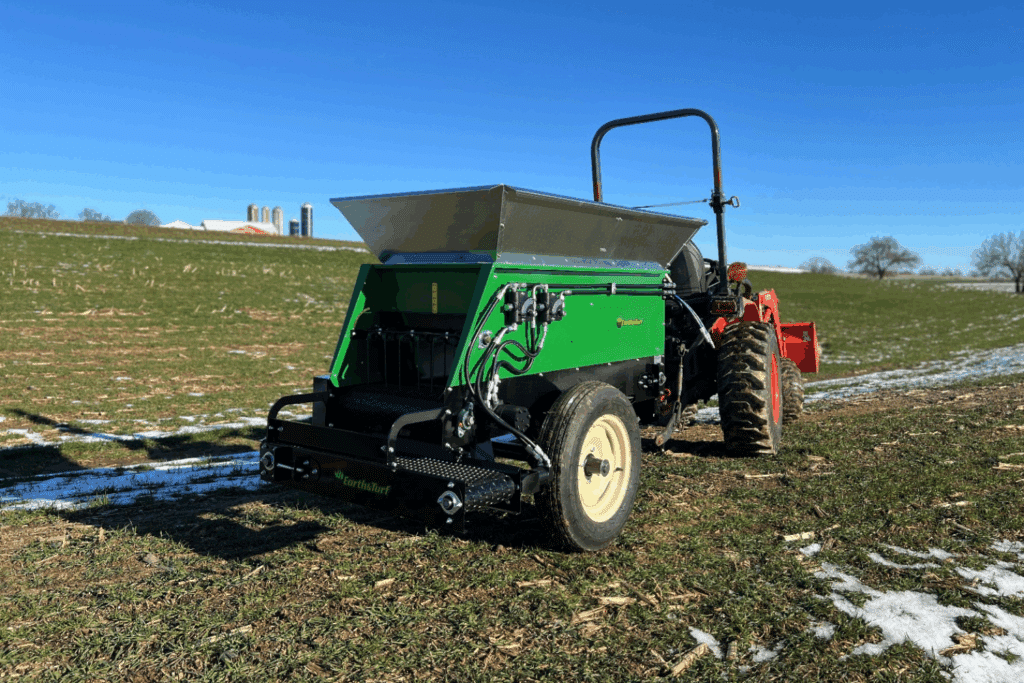

The 220H and 320H are both hydraulic spreaders, built on the foundation of their ground-driven original 220MS and 320MS models. While hydraulic controls require available ports to power the spreader belt and beater mechanisms, they offer next-level control in return.

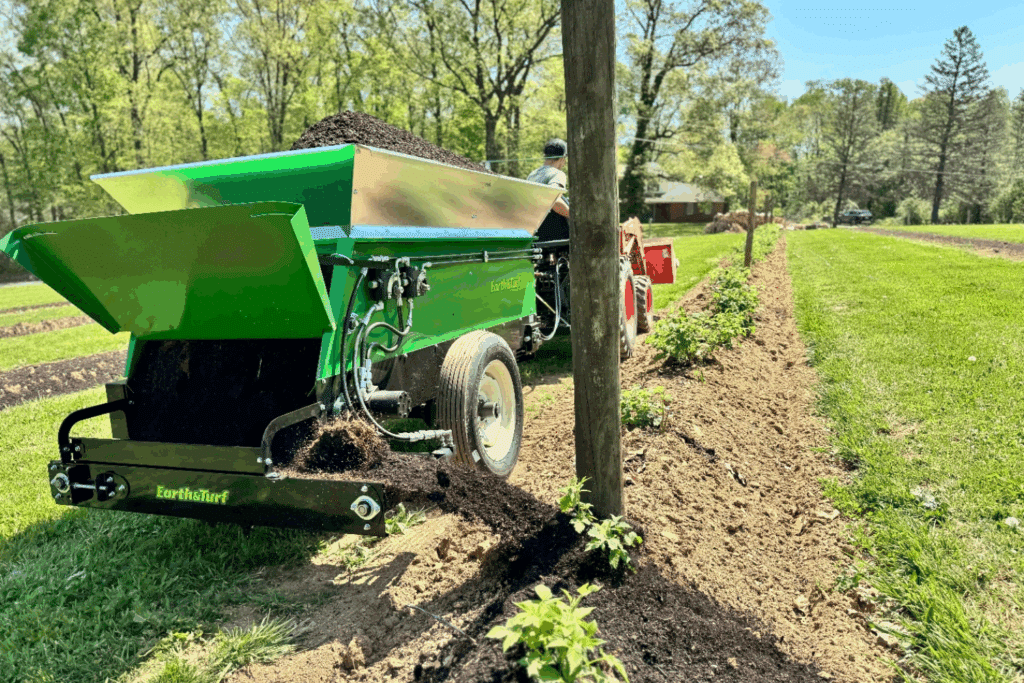

Both the 220H and 320H can be configured in multiple ways to handle topdressing and/or sidedressing, all using the same base machine. Because they’re designed on the main models, they will spread dry or moist materials, including compost, mushroom soil, bark mulch, and wood chips.

These hydraulic spreaders are not always “better” than the ground drive counterparts, but do offer a few other features. A comparison chart shows the differences below:

| Operation Description | Ground Drive Model | Hydraulic Counterpart |

| Spread Multiple Materials | Yes | Yes |

| Spread Thickness Control | Yes, by metering gate | Yes, by metering gate, ground speed, and hydraulic flow |

| Topdress | Yes, beater | Yes, beater |

| Lawn Level | Yes, lightly | Yes, heavy |

| Sidedress | No | Yes, with side conveyor |

| Machine Requirements | Not Available | 20+ HP w/ hydraulic ports |

| Spread Thickness | ⅛” – ¼” | Infinite Control |

Hydraulic oil is pumped from the pulling vehicle’s central hydraulic system into the spreader via a connected line.

The oil first passes through a valve that controls the central conveyor belt. Adjustable flow: You can restrict the flow for a slower belt speed (suitable for light applications) or open it up for faster movement (ideal for heavier applications).

From the first valve, the oil continues to the second valve and then to the motor. Just like the first, this valve can also be adjusted to control flow rate and speed.

Because the system uses hydraulic lines instead of mechanical components like chains or shafts, it’s easy to reroute the oil flow for re-directional movement, which is how the side conveyor and beater can both mount up despite adjacent flow requirements.

After running through the system, the oil returns to the vehicle’s hydraulic reservoir through the return line to be gathered and sent out again.

| Capacity | Approx. 15 cu. ft. (0.42 m3) Standard / 27 cu. ft. (0.75 m3) w/ LMS |

| Max Load Weight | 1,725 lbs. (783 kg) |

| Box Width | 23.5 inches (59.7 cm) |

| Box Length | 57 inches (144.8 cm) |

| Total Height | 37.5 inches (95.3 cm) |

| Total Width | 45 inches (114.3 cm) |

| Total Length | 99.3 inches (252.1 cm) |

| Spread Width | Up to 54 inches (137.16 cm) |

| Spread Thickness | Up to 0.25 inches (0.6 cm) |

| Spread System | Widespread Beater |

| Weight w/ Tires | 475 lbs. (215.5 kg) |

| Tire Size | 20.5 x 8.0-10 |

| Drive | Hydraulic off of the towing vehicle |

| Required Power | 16 HP (12 kW) |

| Build | 12/16 Ga. Bolted Steel, 2-Part Epoxy |

| Capacity | Approx. 27 cu. ft. (1.53 m3) Standard / 54 cu. ft. (1.5 m3) w/ LMS |

| Max Load Weight | 2,700 lbs. (1225 kg) |

| Box Width | 30.5 inches (77.5 cm) |

| Box Length | 73.5 inches (186.7 cm) |

| Total Height | 39.5 inches (100.3 cm) |

| Total Width | 58.8 inches (148.4cm) |

| Total Length | 122 inches (309.9 cm) |

| Spread Width | up to 60 inches (152.4 cm) |

| Spread Thickness | Up to 0.25 inches (0.6 cm) |

| Spread System | Widespread Beater |

| Weight w/ Tires | 760 lbs. (344.7 kg) |

| Tire Size | 26.0 x 12-12 |

| Drive | Hydraulic off of the towing vehicle |

| Required Power | 20 HP (15.5 kW) |

| Build | 12/16 Ga. Bolted Steel, 2-Part Epoxy |

Materials commonly spread by the 220H/320H Side Dresser include: compost, topdressing materials, mulch, and wood chips.

The 220H/320H Compost Spreader is built on the platform of the MultiSpread™ 220 and the MultiSpread™ 320 with the ground-drive swapped out for hydraulic drive.

The 220H/320H Hydraulic topdresser is used mainly by vineyards, orchards, blueberry patches, nurseries, and Christmas Tree Farms to spread compost in and on narrow rows.

Hydraulic models offer more control and flexibility, but they require hydraulic ports on the pulling vehicle. Ideal setup: Ports should be located at the rear of the vehicle. These are commonly found on diesel tractors and occasionally on other machines.

If your vehicle doesn’t have hydraulic ports, you can use a separate engine and hydraulic pump to run the spreader independently. We do not supply any alternatives, but have worked with customers who source them on their own.

The spreader doesn’t rely specifically on engine horsepower (HP), but rather on hydraulic flow rate. You’ll need at least 5 gallons per minute (GPM) of hydraulic flow. This is known as continuous flow, different from short, one-way bursts like those used on a mower deck’s lift cylinder.

| Product | OK for Use? | Results |

|---|---|---|

| Send | Yes | Very high levels of control for even, level spreading, moist or dry sand. |

| Compost | Yes | Smooth flow, dry, fluffy material qualifies for LMS extension sides for more capacity |

| Mushroom Soil | Yes | Moist material may inhibit clean, flowing material, but should spread fine under good conditions – fluff/stir material before loading the spreader LMS extension sides for more capacity |

| Wood Chips/ Bark Mulch | Yes | Fibrous material may inhibit clean, flowing material, but should spread well under good conditions. Keep large sticks out of the hopper to avoid potential damage LMS extension sides for more capacity |

| Ag Lime | No | May damage the spreader by weight/density, making it challenging to control material flow with precision |

| Granular/ Powdered Fertilizer | No | May damage the spreader by corrosiveness, making it challenging to control material flow with precision |

If you are interested in one of our machines, please request a quote for more information on a model tailored to your needs, or contact us directly to speak with a live representative.